Project Examples

|

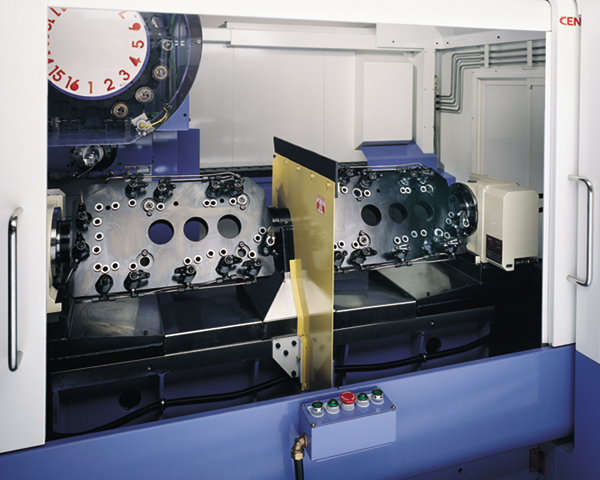

CNC COMMISSION & FIXTURES The KIRA KN 40HS, "Dual Zone Convertible, Horizontal CNC Production Machining Center was commissioned with dual rotary fixtures. The fixtures feature quick change locators for left/right hand part machining. The fixtures are trunnion mounted to 2 NC rotary indexers, each independently controlled. Hydraulic clamping is "Thru the indexer" with a rotary union allowing full 360 degrees rotation of the fixtures. A PLC was added to the machine to control auto clamping and broken tap detection. |

|

TUBE BORING AND ASSEMBLY MACHINE This multiple operation, special machine is designed specifically for aluminum die cast valve covers. This machine drills, reams and chamfers the tube hole in the left hand valve cover, then automatically presses the tube into the hole. The system features automatic feeding of the tube to be inserted, monitoring of the tube pressing force, and automatic fixture unloading.

|

|

COOL DOWN MACHINE This machine is use to cool the valve covers back down to ambient after their exit from the washing machine. It consists of an indexing, stainless steel, open mesh conveyor with cleats approximately every 11 inches. A plenum surrounds the conveyor and houses the cooling fans and excludes any foreign matter from the parts during cool-down.

|

|

LEAK DECAY MACHINE This machine tests Air Leak Decay on die cast aluminum valve covers. A Cosmo instrument tester is used to test to a 2cc per minute leak rate. The machine is equipped with a master station and a test station, to eliminate all variables due to temperature and pressure. The test covers are hydraulically clamped to a special molded urethane gasket that seals the cover to the base.

|

|

ASSEMBLY MACHINE The Assembly Machine was designed to insert three rubber grommets into a die cast aluminum valve cover. The operator loads the valve cover onto the tooling (valve cover open side up), places three rubber grommets on three different inserting tools, and press the cycle start button. Each inserter is equipped with a load cell, that checks pressure of force. After the cycle is complete the cover is automatically unloaded from the nest and places the valve cover in front of the machine.

|

|

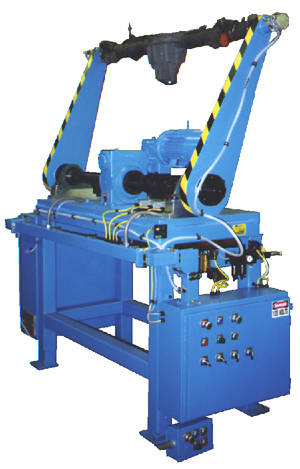

OVERHEAD TRANSFER MACHINE The Overhead Transfer Machine is a fully automatic machine that will transfer the axle assembly's from the existing Piercing Machine onto the existing conveyor. The Overhead Transfer Machine consists of a heavy duty machine base, operator controls, pick and place transfer arms, and a 300:1 power unit. The Overhead Transfer Machine arms rotates down above the Piercing Machine and holds position. The locating plugs extend inside the housing ends, which hold the axle assembly while being transferred. The Overhead Transfer arms rotate approximately 185° to the existing conveyor. The locating plugs retract out of the housing ends, which releases the axle assembly on top of the conveyor's nest.

|

|

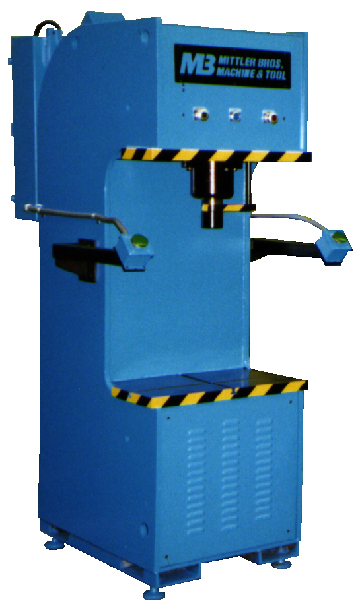

PRESS MACHINE The Press Machine is used for a variety of applications up to the press's highest force. The press is capable of 20,000 Ibs of pressing force, with a low pressure (1000 psi) hydraulic system. The machine controls include Allen Bradley SLC-500 rack type PLC for machine controls and functions. Lighted push-button Power and E-Stop controls with push-button operator functions, and dual anti-tie down cycle start buttons for safe operations. Built into the back of the machine is the Hydraulic Power Unit with 30 gal. reservoir and 10 hp pump unit to provide 10 gpm @ 1000 psi. |

|

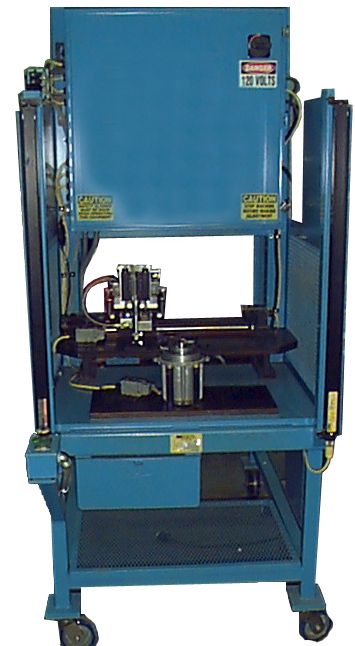

SEMI-AUTOMATIC RTV MACHINES The semi-automatic RTV machine is a X-Yaxis dispensing machine that automatically puts a bead of RTV on the clutch housing. The machine consists of a machine base, X-V slide, application area, and operator controls. Machine consist of 2 servo driven ball-screw assemblies transverse mounted with a pneumatic slide. The pneumatic slide has 2 inches of total movement for the Zaxis, to raise and lower the applicator head. The application area consists of a part nest to accept the clutch housing for application and activate part present switch when housing is present. |